1. Trends

With the increasing trend toward electric, driverless technology and new energy vehicles, lightweighting will become an inevitable trend in automotive design. Plastics is key in realizing this vision; extensive use in this sector will open up exciting historic opportunities for them both!

In October 2018 China Society of Automotive Engineers published “Technology Roadmap for Energy-Saving and New Energy Vehicles.” According to this roadmap, quality of complete vehicles expected to decrease 10%-20-20-35% relative to 2016 respectively in 2020-2025-2030 respectively compared with 2016. Automotive industry is anticipated to experience rapid increases in plastics consumption over time which in turn promote rapid expansion within injection mold industry.

2. Composition of interior and exterior decoration of automobile

The instrument panel assembly of the automobile interior mainly includes the main instrument panel assembly, the instrument panel tubular beam assembly, and the auxiliary instrument panel assembly.

Interior panel assembly of automobile side panel

Interior panel assembly of SUV side panel

Interior door panel assembly of automobile

Roof assembly of automobile

Front and rear bumper assembly of automobile

Rear door panel assembly of automobile

Automobile fender assembly

Automotive lighting assembly

3.Common Materials for Automotive Interior and Exterior

The common plastics used in automotive interior and exterior parts mainly include PP, PU, ABS (including ABS and PC+ABS), PE, PA and POM, among which PP is the most commonly used material.

4. Automotive Mold in Interior and Exterior Decorating Solutions

Automotive mold industry growth is tied directly to its rapid expansion. Recent years have witnessed dramatic transformation of global automotive mold industries and demand for automotive molds; each new car requires approximately 500 pairs of automotive molds. Market share for automobile products has already exceeded 60% in developed nations’ automobile markets and this trend continues. It can be said that injection molds comprise the vast majority of automotive molds produced, underlining their significance.

5. Advanced technology of injection molds for automotive interior and exterior trims

There is no essential difference between automotive injection molds and other injection molds, but they also have many unique characteristics. Because automotive injection molds generally have higher added value, many advanced technologies (such as sequential valve hot runner control technology, internal parting surface technology, low pressure injection technology, etc.) are prioritized for development and application in automotive injection molds.

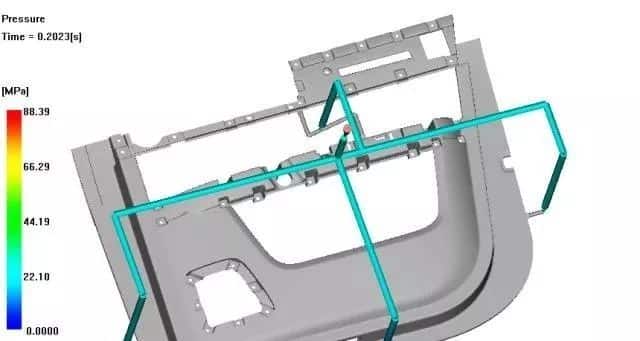

1. Sequential valve hot runner control technology (SVG technology)

The sequential valve hot runner control technology (SVG technology) is a new type of stage-controlled hot runner technology that uses oil cylinders to control the sequential injection of glue, solving the problem of appearance defects in traditional multi-point synchronous injection products. It can effectively avoid defects such as weld marks and air pockets in automotive interior and exterior trims, reduce flow length, lower molding pressure, and play a significant role in automotive interior and exterior trims with strict appearance requirements.

2. Low-pressure double-layer injection mold technology

The so-called low-pressure double-layer injection mold, also referred to as low-pressure injection mold, is a new type of injection mold technology that directly injects parts into the mold in one step, replacing traditional manual cladding and vacuum adsorption of male and female molds. The main principle of low-pressure injection mold is that the plastic with low injection pressure flows on the cloth. When opening the mold, the cloth should be hung on the front mold needle first, then the mold is closed, injected, and finally the part is taken out. The products produced by this technology have a special soft cloth layer on the surface, which greatly improves their decorative, hand feel, and aesthetic properties. Therefore, low-pressure injection mold technology is widely used in medium and high-end automobiles, generally applied to parts such as car map bag skeletons and car ABC pillars.

3. Injection mold technology for automobile bumper inner parting

In automotive injection molds, advanced internal parting surface technology is often used for automotive bumper products during mold design. The advantage is that the parting line is hidden on the non-appearance surface of the bumper, and after assembly on the car, the appearance line cannot be seen, which does not affect the appearance of the product. However, this technology is more complex in terms of difficulty and structure than external parting bumper, and the technical risk is also higher. The mold cost and mold price are also much higher than external parting bumper, but due to its beautiful appearance, it is widely used in medium and high-end cars.