Welcome to DIAMONDMOLD

About us

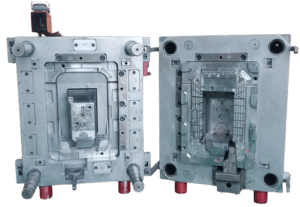

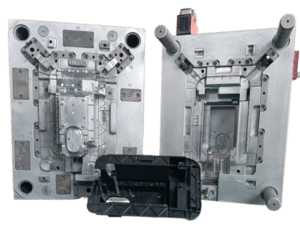

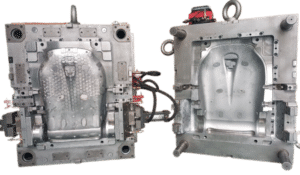

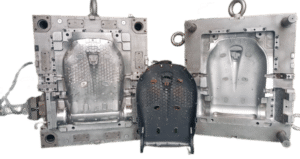

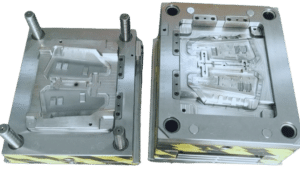

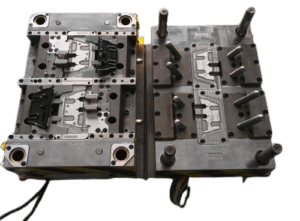

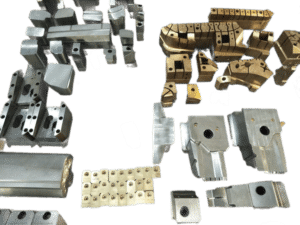

Our Products

Our values

Core Values

01

Integrity

We uphold the highest standards of honesty and ethical practices in all our endeavors.

02

Collaboration

We foster strong partnerships with our clients to achieve mutual success and growth.

03

Innovation

We continuously strive to explore new ideas and technologies to drive excellence.

Why Choose Us

Our Unique Value Proposition

Discover the distinguishing factors that set Shenzhen Diamondmold apart from the competition.

Precision Engineering

Our meticulous approach ensures precise and flawless plastic components for your projects.

Client-Centric Approach

Tailored solutions and dedicated customer support make your satisfaction our top priority.

Streamlined Processes

Efficient workflows guarantee timely delivery without compromising on quality.